Adjustable suspension systems offer customization for smoother rides or enhanced handling but face degradation over time due to regular use and environmental factors, leading to part failures like shock absorbers, springs, and control arms. Miscalibration can cause uneven tire wear and safety hazards, emphasizing the importance of regular maintenance, timely replacement of worn parts, adherence to manufacturer guidelines, and professional tuning for optimal performance and safety.

Adjustable suspension systems, a modern twist on vehicle dynamics, promise tailored ride qualities. However, these sophisticated mechanisms aren’t immune to issues. From component wear to calibration challenges, various problems can arise. This article delves into the intricacies of common problems plaguing adjustable suspension systems, examining components and their wear, calibration complexities, and prevalent failure points. By understanding these challenges, drivers and mechanics alike can better maintain and prevent potential pitfalls associated with this advanced technology.

- Components and Their Wear: An In-depth Look

- Calibration and Adjustment Issues

- Common Mechanisms of Failure and Prevention Strategies

Components and Their Wear: An In-depth Look

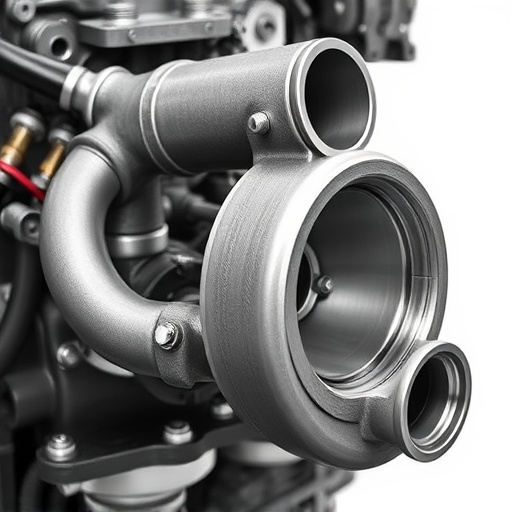

The adjustable suspension system, while offering customization for a smoother ride or enhanced handling, comprises several interconnected components that are subject to wear over time. These include shock absorbers, springs, struts, and control arms—all working in harmony to maintain vehicle stability and comfort. Regular use, varying driving conditions, and exposure to harsh elements contribute to the gradual deterioration of these parts. For instance, shock absorbers can develop leaks or lose their ability to effectively dampen road irregularities due to metal fatigue or contamination. Springs might become compressed or damaged, affecting the vehicle’s height and ride quality. Struts, which play a critical role in maintaining alignment and stability, can also succumb to corrosion or component failure over time.

Moreover, other essential components like brake rotors, integral to the braking system that supports the adjustable suspension, are equally susceptible to wear. A compromised brake rotor can lead to reduced braking efficiency, impacting both safety and control. Even exhaust systems, although not directly related to suspension adjustment, can influence overall vehicle performance and handling when integrated into the suspension setup (e.g., cat-back exhaust systems). Regular maintenance, including timely replacement of worn parts, is crucial to ensure optimal performance from an adjustable suspension system, preserving both safety and driving enjoyment.

Calibration and Adjustment Issues

One of the primary challenges with adjustable suspension systems is calibration and adjustment. These systems rely on precise settings to balance vehicle handling and comfort, but getting them just right can be tricky. Miscalibration can lead to uneven tire wear, poor handling, or even safety hazards. Even small adjustments, if not done correctly, might significantly impact the overall performance of the brakes and steering.

Regular maintenance is crucial to addressing these issues. Using high-quality air filter kits ensures optimal airflow, which in turn helps keep suspension components clean and functioning optimally. Additionally, professional tuning services can help fine-tune settings to enhance vehicle performance, ensuring that the adjustable suspension system operates at its peak under various driving conditions.

Common Mechanisms of Failure and Prevention Strategies

The primary mechanisms of failure in adjustable suspension systems often stem from several interconnected factors. One common issue is excessive wear on bushings and bearings due to improper adjustment or prolonged use without regular maintenance. This can lead to uneven tire wear, handling problems, and, in severe cases, safety hazards. Another frequent problem involves the control arm or ball joint connections loosening over time, resulting in reduced steering precision and increased noise during driving.

Prevention strategies for these issues involve consistent and correct adjustment of the suspension according to manufacturer recommendations. Regular inspection of all components, especially bushings and joints, is crucial. Upgrading to high-quality replacement parts can significantly prolong the lifespan of an adjustable suspension system. For exhaust systems, including cat back exhausts and exhaust tips, proper installation and maintenance are equally important to avoid heat-related damage that could compromise the structural integrity of the suspension components.

Adjustable suspension systems, while offering customization and performance benefits, are not immune to problems. Through understanding common issues like components wear, calibration difficulties, and failure mechanisms, vehicle owners can ensure optimal performance and longevity of their adjustable suspension. Regular maintenance, proper calibration, and awareness of potential failure points are key strategies to keep these systems running smoothly. By addressing these concerns, you can maximize the advantages of an adjustable suspension system for a safer and more enjoyable driving experience.